In the world of metals and recycling, distinguishing between ferrous and non-ferrous metals is foundational knowledge. From industrial applications to DIY projects, understanding these materials’ properties, uses, and recyclability can greatly enhance how we interact with the world around us.

In this post, we’re diving deep into the fascinating differences and similarities between these two metal categories. Whether you’re a recycler, a member of the DIY community, a metal enthusiast, or an engineering professional, this guide is for you.

So let’s start with the basics…

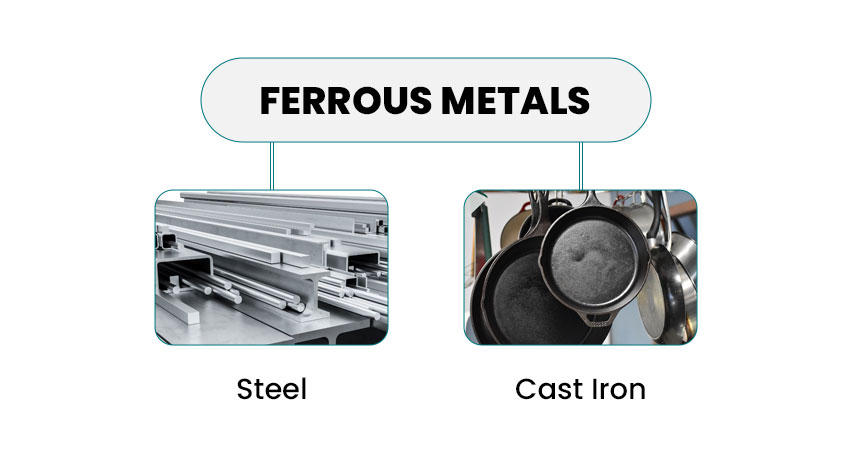

What are ferrous Metals?

A ferrous metal is one which contains iron. Ferrous metal is known for its strength and durability, making it ideal for use in construction and industrial applications. Common examples include steel and cast iron. Most other ferrous metals and ferrous materials are alloys, which means they contain a mixture of iron and other elements.

One defining characteristic of ferrous metals is their magnetic properties, which is due to the iron content.

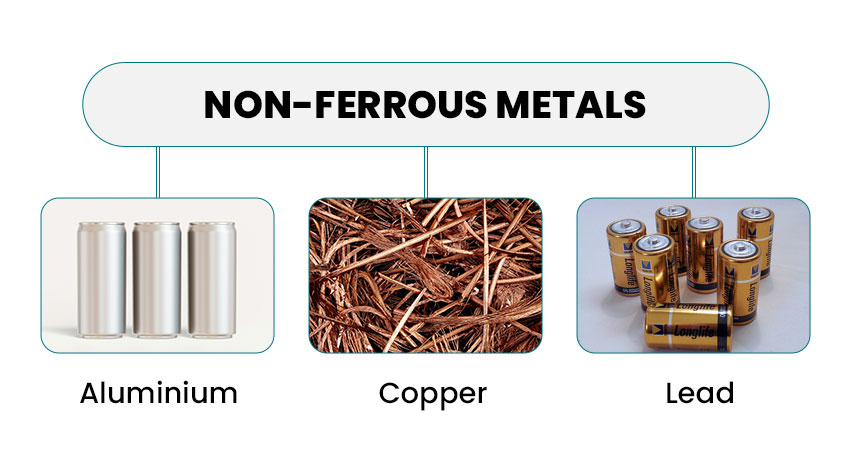

What are non-ferrous Metals?

A non-ferrous metal, on the other hand, is a metal that does not contain significant amounts of iron. This category includes a wide variety of metals such as aluminium, copper, lead, zinc, and tin.

Key differences

The primary difference between ferrous and non-ferrous metals is the presence, or lack thereof, of iron. This distinction leads to a number of characteristics that set these two groups apart.

For instance, ferrous metals tend to be stronger and heavier, making them suitable for infrastructure and heavy-duty applications. On the flip side, non-ferrous metals are chosen for their specific properties such as lighter weight, higher conductivity, and resistance to corrosion.

Examples of each

Common ferrous metals include:

- Steel: Used in construction, automotive, and many other industries.

- Cast iron: Common in pipes, automotive components, and cookware.

Most ferrous metals are alloys, meaning they are a combination of multiple metals. For example, stainless steel is an alloy that contains iron, chromium, and nickel.

Non-ferrous metals include:

- Aluminium: Used in aircraft construction, beverage cans, and electrical wiring.

- Copper: Used in industrial piping, wires, and electrical components due to its high conductivity.

- Lead: Commonly found in batteries, weights, and ammunition.

Properties of each

Ferrous metals are generally stronger and more durable but are prone to rust when exposed to moisture. This is where non-ferrous metals shine (literally)—most do not rust, with aluminium forming a protective oxide layer.

Moving beyond the basic distinctions, it is crucial to explore the mechanical properties and melting points of ferrous and non-ferrous metals to understand their applicability in various environments and conditions.

Mechanical Properties

Mechanical properties include aspects like tensile strength, ductility, hardness, and malleability. Ferrous metals, particularly steel and its alloys, exhibit high tensile strength and durability, which is why they are favoured in construction and machinery.

However, they can be less malleable and ductile compared to some non-ferrous metals. Non-ferrous metals such as aluminium or copper, while not matching the strength of ferrous metals, bring excellent ductility and malleability to the table, making them ideal for electrical wiring, pipes, and in applications where forming metals into specific shapes is required.

Melting Points

The melting point of a metal significantly affects its processing and application. Ferrous metals usually have higher melting points. This characteristic makes them more suitable for high-temperature applications but also means they require more energy to melt and work with. For example, steel’s melting point ranges from 1370°C to 1510°C (2500°F to 2750°F), which stands in contrast to aluminium’s low melting point of approximately 660.3°C (1220.5°F), making aluminium easier to cast, weld, and shape.

Understanding the distinct properties of ferrous and non-ferrous metals, including their mechanical properties and melting points, enables engineers, designers, and architects to select the most appropriate materials for their specific needs, balancing factors like strength, weight, conductivity, and corrosion resistance.

Recycling ferrous and non-ferrous metals

One of the most significant differences between ferrous and non-ferrous metals is their recyclability. While both types can be recycled, they have different processes and markets for recycling.

Ferrous metals are typically recycled in large quantities through industrial processes that use magnets to separate them from other materials. These metals are then melted down and used to make new products.

Non-ferrous metals, on the other hand, require more specialised recycling facilities. They are usually separated by type and melted down to be reused in a variety of applications.

Recycling not only conserves raw materials and energy but also reduces greenhouse gas emissions, contributing to environmental preservation.

FAQ

Can non-ferrous metals be magnetised?

Generally, no. The lack of iron content means non-ferrous metals are not magnetic, which helps in sorting them from ferrous metals during recycling.

Are ferrous metals more valuable than non-ferrous metals?

In terms of recycling, non-ferrous metals often carry a higher value due to their rarity and unique properties, such as conductivity and resistance to corrosion.

What’s the difference between steel and carbon steel and iron and wrought iron?

Steel is an alloy of iron and carbon, while carbon steel refers to steel with a higher carbon content. Similarly, wrought iron is a type of iron that contains very low levels of carbon, making it malleable and easier to work with.

How can I tell if a metal is ferrous or non-ferrous?

One quick test is to use a magnet; if it sticks, the metal is ferrous. For a more precise determination, consider the metal’s characteristics and applications.

Why is recycling metals important?

Recycling metals significantly reduces the impact on the environment, decreases energy consumption, and conserves natural resources.

What is the most recycled metal?

Steel is the most recycled material worldwide, due in part to its extensive use in various industries.

Are gold, silver and bronze ferrous or non-ferrous?

Gold, silver, and bronze are classed as precious metals and are all non-ferrous. They do not contain iron and have unique properties that make them valuable for jewellery making and other decorative applications. However, they are not commonly used in industrial or construction settings due to their high cost and limited availability compared to other non-ferrous metals. So while gold, silver, and bronze may not fall neatly into the categories of ferrous or non-ferrous, they are still important and valuable metals in their own right.

Conclusion

Understanding the distinction between ferrous and non-ferrous metals is not just academic—it impacts decisions made by engineers, recyclers, and DIYers alike.

Each type of metal serves unique purposes in our daily lives and offers specific benefits. Furthermore, their recyclability underscores the importance of sustainability in our modern world.

If you’re looking to learn more about how you can recycle ferrous or non-ferrous metals, or if you’re curious about the recycling services available, reach out to Mackers Metals. Our expertise ensures that metal waste is handled responsibly, contributing to a greener planet.

Remember, every piece of metal recycled is a step towards a more sustainable future. Contact Mackers Metals today to find out how you can make a difference.